TC2 Titanium Alloy Aheet Plate

TC2 Titanium Alloy Aheet Plate, Alloy ku salaysan titanium oo leh walxo kale oo lagu daray.Waxaa jira laba nooc oo kiristaalo isku mid ah oo ku jira titanium: α titanium oo leh qaab dhismeed laba geesood ah oo cufan ayaa ka hooseeya 882℃, iyo β titanium oo leh cube xarun jidheed ayaa ka sarreysa 882℃.

Shuruudaha farsamada:

1. Halabuurka kiimikada ee titanium iyo titanium alloy saxan waa in ay u hoggaansamaan qodobada GB/T 3620.

2. Arrinka dib-u-eegista, weecinta la oggol yahay ee ka kooban kiimikada waa inay u hoggaansamaan qodobada GB/T 3620.

a.weecanka la ogolyahay ee dhumucda saxanka waa in uu waafajiyaa qodobada shaxda 1.

b.weecanka la ogol yahay ee ballaca iyo dhererka saxanka waa in uu waafaqsan yahay qodobada shaxda 2.

c.geesaha saxanka waa in la gooyaa xaglaha saxda ah ee suurtogalka ah.leexashadu waa in aanay dhaafin dhererka iyo ballaca xaashida

TC2 Titanium Alloy Aheet Plate, Tilmaamaha Wax soo saarka

T 0.5-1.0mm × W1000mm × L 2000-3500mm

T 1.0-5.0mm × W1000-1500mm × L 2000-3500mm

T 5.0- 30mm × W1000-2500mm × L 3000-6000mm

T 30-80mm × W1000mm × L 2000mm

TC2 Titanium Alloy Aheet Plate, Heerka Wax soo saarka

Xaalad shaqo oo kulul (R) Xaalad shaqo qabow (Y) Gobolka Annealing (M)

TC2 Titanium Alloy Aheet Plate, Heerka Tixraaca

1: GB 228 Habka tijaabada xajinta birta

2: GB/T 3620.1 Titanium iyo titanium alloy darajooyin iyo halabuurka kiimikada

3: GB/T3620.2 Titanium iyo titanium daawaha la warshadeeyey alaabta ka kooban kiimikada iyo ka kooban weecasho la ogol yahay

4: GB 4698 Habka dusha badda ee falanqaynta kiimikada ee titanium, titanium iyo ferroalloys

TC2 Titanium Alloy Aheet Plate, Shuruudaha Farsamada

1: Halabuurka kiimikada ee titanium iyo titanium alloy saxan waa in ay u hoggaansamaan qodobada GB/T 3620.1.Xaaladda dib-u-eegista, weecinta la oggol yahay ee ka kooban kiimikada waa inay u hoggaansamaan qodobada GB/T 3620.2.

2: Weecanka la ogolyahay ee dhumucda saxanka waa in uu waafajiyaa qodobada shaxda 1.

3: Weecanka la ogol yahay ee ballaca iyo dhererka saxanka waa in uu waafaqsan yahay qodobada shaxda 2.

4: geesaha saxanka waa in la gooyaa xagal toosan inta suurtogalka ah.leexashadu waa in aanay dhaafin dhererka iyo ballaca xaashida

Alloying

TC2 Titanium Alloy Aheet Plate, Alloy ku salaysan titanium oo leh walxo kale oo lagu daray.Waxaa jira laba nooc oo kiristaalo isku mid ah oo ku jira titanium: α titanium oo leh qaab dhismeed laba geesood ah oo cufan ayaa ka hooseeya 882℃, iyo β titanium oo leh cube xarun jidheed ayaa ka sarreysa 882℃.

(1) Walxaha Alloying waxa loo qaybin karaa saddex qaybood iyadoo loo eegayo saamaynta ay ku leeyihiin heerkulka kala-guurka wejiga:

Curiyayaasha α-deggan, sida aluminium, kaarboon, ogsijiin iyo nitrogen, waxay dejiyaan wajiga α waxayna kordhiyaan heerkulka kala-guurka wajiga.Aluminiumku waa sheyga ugu muhiimsan ee daawaha titanium, kaas oo leh saameyn muuqata oo lagu hagaajinayo xoogga daawaha heerkulka qolka iyo heerkulka sare, yaraynta cufnaanta gaarka ah iyo kordhinta moodeelka dabacsanaanta.

(2) walxaha β-stable waxaa loo qaybin karaa laba nooc: isocrystalline iyo eutectoid.Alaabooyinka ka samaysan titanium alloy

Midka hore wuxuu leeyahay molybdenum, niobium, vanadium iyo wixii la mid ah;Tan dambe waxay leedahay chromium, manganese, copper, iron, silicon iyo wixii la mid ah.

(3) Walxaha saameyn yar ku leh heerkulka kala-guurka wajiga waa walxo dhexdhexaad ah, sida zirconium iyo tiin.

Ogsajiinta, nitrogen, kaarboon iyo hydrogen ayaa ah wasakhda ugu weyn ee ku jirta alloys titanium.Xalka oksijiinta iyo nitrogen ee wajiga α ayaa ka weyn, taas oo saameyn weyn ku leh xoojinta titanium-ka, laakiin waxay hoos u dhigtaa caagga.Waxa ku jira ogsajiinta iyo nitrogen ee titanium inta badan way ka hoosaysaa 0.15 ~ 0.2% iyo 0.04 ~ 0.05%, siday u kala horreeyaan.Hydrogen waxay leedahay milmayn aad u yar wajiga α, iyo hydrogen aad u badan oo ku milmay alloys titanium waxay soo saartaa hydrides, taas oo ka dhigaysa daawaha jajaban.Maaddooyinka hydrogen ee ku jira daawaha titanium waxaa badanaa lagu xakameeyaa wax ka hooseeya 0.015%.Kala dirida hydrogen ee titanium waa dib loo rogi karaa waxaana lagu saari karaa nadiifinta faakuumka.

Halabuurka Kiimikada

| Darajo | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

Xoogga Jilicsan

| Darajo | Dheeraynta(%) | Xoogga Jilitaanka (min) | Xoogga Wax-soosaarka (Daqadda) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |

Titanium iyo Aloy Products

| Magaca alaabta | Tilmaamaha |

| Titanium Rod & Bar & Ingots | Ф3mm ~ 1020mm, miisaanka ugu badan waa ilaa 12t |

| Titanium Slab | (80~400)mm×(~1500)mm×(~2600)mm |

| Titanium Forgings | Miisaanka gabalkiiba≤2000kg |

| Titanium Taargo kulul oo duuban | (4 ~ 100) mm × (800 ~ 2600) mm × (2000 ~ 12000) mm |

| Titanium Sheet Qabow-duuban | (0.01~4.0)mm×(800~1560)mm×(~6000) mm |

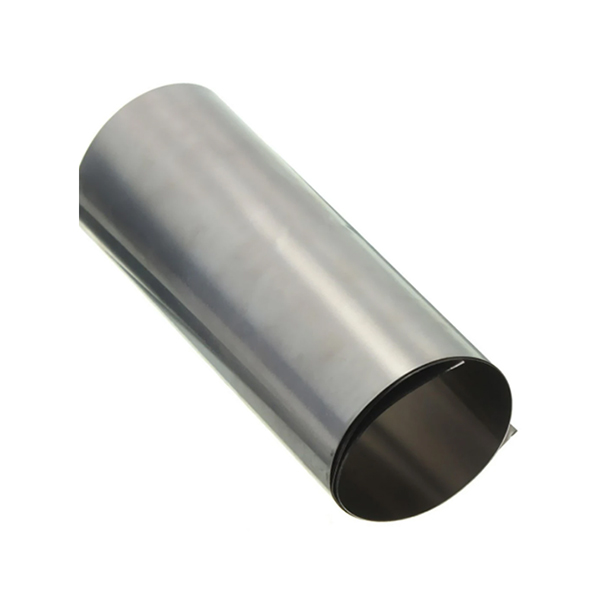

| Titanium Foil / Strips | (0.01~2.0)mm×(800~1560)mm×L |

| Tubooyinka Titanium / Tubooyinka | Ф (3 ~ 114) mm × ( 0.2 ~ 5) mm × (~ 15000) mm |

| Heerarka | GB,GJB,ASTM,AMS,BS,DIN,DMS,JIS,ГОСт |

| Darajada Titanium |

|

Bandhiga Alaabta