L485 dhuumaha birta ee warshadaha batroolka

L485 Pipeline Steel, Waxa loola jeedaa nooc bir ah oo leh shuruudo gaar ah oo loo isticmaalo gudbinta saliidda, gaaska dabiiciga ah iyo dhuumaha kale.Marka loo eego dhumucda iyo samaynta soo socota iyo dhinacyo kale, waxaa lagu soo saari karaa warshad-shiid kiimikaad kulul, steckel ama warshad saxan ah, oo lagu sameeyay alxanka wareegyada ama UOE alxanka tolida tooska ah ee tuubada birta dhexroor weyn.

Birta Dhuumaha L485, Hordhac The

Gaadiidka dhuumaha qaada iyo gaadiidka tareenada, gaadiidka wadooyinka waaweyn, gaadiidka marin biyoodka iyo gaadiidka hawada ayaa loo taxay shan nooc oo gaadiid oo casri ah.Laga soo bilaabo dhuumihii hore ee warshadaha ilaa hadda, dhismaha dhuumaha saliidda iyo gaasta waxay la kulmeen ku dhawaad laba qarni oo horumar ah.Wax soo saarka iyo codsiga birta dhuumaha ayaa ka bilaabmay Shiinaha, mana jirin wax soo saar bir ah oo dhab ah ka hor 1985. Si kastaba ha ahaatee, sanadihii ugu dambeeyay, horumarinta, horumarinta iyo codsiga birta dhuumaha ee Shiinaha ayaa si degdeg ah u horumaray.Iyada oo kor loo qaadayo mashaariicda waaweyn ee dhuumaha sida dhuumaha galbeedka, dhuumaha gudbinta gaaska galbeed-bari iyo gaaska galbeed-bari ee gudbinta dhuunta labaad ee gaaska, soo saarista iyo codsiga birta dhuumaha ee X60, X70 iyo X80 ayaa si isdaba joog ah loo dhammeeyey, natiijooyinka cilmi-baarista X100 iyo X120 ayaa la helay.

L485 Birta Dhuumaha, Noocyada unugyada

L485 Pipeline Steel, Qaab dhismeedka ururku waa aasaaska go'aaminta waxqabadkeeda iyo adeeggeeda badbaadada leh.Waqtigan xaadirka ah, biraha dhuumaha waxaa loo qaybin karaa afarta qaybood ee soo socota iyadoo loo eegayo qaab-dhismeedkooda yar:

1. Ferritic pearlite pipeline pipeline steel

Birta dhuumaha birta ah ee pearlite waa qaabka aasaasiga ah ee birta dhuumaha ee la sameeyay ka hor 1960-kii.X52 iyo birta dhuumaha oo leh heer hoose oo xoog ah dhamaantood waa pearlite ferritic ah.Qaybaheeda aasaasiga ah waa kaarboon iyo manganese, iyo kaarboonka (jajab tiro, isla hoos) waa 0.10% ilaa 0.20%, iyo maadada manganese waa 1.30% ilaa 1.70%.Guud ahaan isticmaal soo saarista habka daawaynta kulul ama duubka kulul.Marka xoog sare loo baahan yahay, xadka sare ee ka kooban kaarboon waa suurad wacan, ama raad niobium iyo vanadium lagu daro nidaamka manganese.Biraha dhuumaha birta ah ee pearlite waxaa guud ahaan loo arkaa inay leeyihiin ferrite geeso badan leh oo cabirkiisu yahay 7μm iyo pearlite oo leh jajab mug ah oo ku saabsan 30%.Biraha tuubada pearlite ee caadiga ah waa 5LB, X42, X52, X60, X60 iyo X70.

2. Acicular ferrite dhuumaha birta

Cilmi-baadhista birta birta ah ee acicular ferritic waxay bilaabatay dabayaaqadii 1960-meeyadii waxaana la geliyay wax soo saarka warshadaha horraantii 1970-meeyadii.Waqtigaas, nidaamka manganese - niobium ee ku salaysan E wuxuu sameeyay kaarboon hooseeya.In mn-Mo-Nb microalloy pipeline steel, ku darida molybdenum waxay yarayn kartaa heerkulka isbeddelka si loo joojiyo samaynta ferrite polygonal, kor u qaadista isbeddelka ferrite acicular, iyo hagaajinta saameynta xoojinta roobabka ee kaarboon iyo niobium nitride, si loo kordhiyo xoogga birta. oo ay yareeyaan adkaanta iyo heerkulka kala-guurka ee jajaban.Tignoolajiyadan alloying molybdenum waxa ay soo saarnayd ku dhawaad 40 sano.Sanadihii la soo dhaafay, tignoolajiyada heerkulka sare ee kale si loo helo ferrite acicular ayaa soo baxaya.Waxay ku heli kartaa ferrite acicular heerkul sarreeya iyadoo la isticmaalayo tignoolajiyada alloying niobium sare.Biraha dhuumaha ferrite ee caadiga ah waa X70 iyo X80.

3. Bainite - birta dhuumaha martensite

Iyadoo horumarinta cadaadiska sare iyo qulqulka weyn ee dhuumaha gaaska dabiiciga ah ee birta iyo raadinta dhimista kharashka dhismaha dhuumaha, qaab dhismeedka ferrite acicular ma buuxin karo shuruudaha.Dabayaaqadii qarnigii 20aad, waxaa soo baxay nooc ka mid ah birta dhuumaha qaada ee xoogga aadka u sarreeya.Darajooyinka birta ee caadiga ah waa X100 iyo X120.X100 waxaa markii ugu horreysay soo warisay SMI ee Japan 1988. Sannado badan oo cilmi baaris iyo horumarin ah ka dib, tuubada X100 ayaa markii ugu horreysay la dhigay qaybta imtixaanka injineernimada 2002. ExxonMobil ee Mareykanka ayaa bilaabay cilmi-baarista X120 birta dhuumaha ee 1993, iyo in 1996, waxay iskaashi la samaysay SMI iyo NSC ee Japan si wadajir ah kor loogu qaado habka cilmi-baarista ee X120.Sannadkii 2004, birta X120 ayaa markii ugu horreysay la dhigay qaybta tijaabada ee dhuumaha.

Naqshadaynta ka kooban birta birta bainite-martensitic, isku dhafka ugu fiican ee kaarboon - manganese - copper - nickel - molybdenum - niobium - vanadium - titanium - boron ayaa la doortay.Naqshadaynta daawayntan waxay si buuxda u isticmaashaa sifooyinka muhiimka ah ee boron ee dhaqdhaqaaqa isbeddelka marxaladda.Ku darida boron raadraaca (ωB=0.0005% ~ 0.003%) waxay si cad u joojin kartaa nukleation of ferrite ee xudduudaha hadhuudhka austenite waxayna ka dhigi kartaa qalooca ferrite dhanka midig si cad. Xataa kaarboon-hooseeya (ωC=0.003%) Qalooca kala-guurka bainite waa la simay iyadoo hoos loo dhigayo heerkulka qaboojinta ee ugu dambeeya (& LT; 300 ℃) iyo hagaajinta heerka qaboojinta (> 20 ℃ / s), bainite hoose iyo qaab dhismeedka lath martensite sidoo kale waa la heli karaa.Biraha tuubooyinka caadiga ah ee bainite-martensite (B -- M) waa X100 iyo X120.

4. birta dhuumaha sophorite ee xanaaqsan

Horumarinta bulshada, birta dhuumaha ayaa looga baahan yahay inay yeeshaan xoog sare iyo adag.Haddii tikniyoolajiyadda duubista iyo qaboojinta la xakameeyey aysan buuxin karin shuruudahan, habka daaweynta kulaylka ee deminta adag iyo xanaaqa ayaa la qaadan karaa si loo buuxiyo shuruudaha dhamaystiran ee darbiga qaro weyn, xoogga sare iyo adagaanta ku filan iyada oo la samaynayo sorbitite xanaaqsan.In birta dhuumaha, sortensite this homogenous, oo sidoo kale loo yaqaan martensite homogenous, waa qaab urureed ee bir X120 xoog ultra-sare leh.

Halabuurka Kiimikada

L245 Pipeline Steel, qaacidada xisaabinta miisaanka

| Halabuurka kiimikada (jajab tiro)…/% | Kaarboon u dhigma (CEV) | |||||||||||||||||

| C | Si | Mn | P | S | Nb | V | Ti | Cr | Ni | Cu | N | Mo | B | Als | ||||

| ka yar ama la siman |

| ka yar ama la siman | ||||||||||||||||

| Q345 | A | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 |

|

|

| 0.3 | 0.5 | 0.2 | 0.012 | 0.1 |

|

| 0.45 | |

| B | 0.035 | 0.035 |

|

|

|

|

| |||||||||||

| C | 0.03 | 0.03 | 0.07 | 0.15 | 0.2 |

| 0.015 | |||||||||||

| D | 0.18 | 0.03 | 0.025 |

| ||||||||||||||

| E | 0.025 | 0.02 |

| |||||||||||||||

| Q390 | A | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 | 0.07 | 0.2 | 0.2 | 0.3 | 0.5 | 0.2 | 0.015 | 0.1 |

|

| 0.46 | |

| B | 0.035 | 0.035 |

|

| ||||||||||||||

| C | 0.03 | 0.03 |

| 0.015 | ||||||||||||||

| D | 0.03 | 0.025 |

| |||||||||||||||

| E | 0.025 | 0.02 |

| |||||||||||||||

| Q420 | A | 0.2 | 0.5 | 1.7 | 0.035 | 0.035 | 0.07 | 0.2 | 0.2 | 0.3 | 0.8 | 0.2 | 0.015 | 0.2 |

|

| 0.48 | |

| B | 0.035 | 0.035 |

| 0.015 | ||||||||||||||

| C | 0.03 | 0.03 |

| |||||||||||||||

| D | 0.03 | 0.025 |

| |||||||||||||||

| E | 25 | 0.02 |

| |||||||||||||||

| Q450 | C | 0.2 | 0.6 | 1.8 | 0.03 | 0.03 | 0.11 | 0.2 | 0.2 | 0.3 | 0.8 | 0.2 | 0.015 | 0.2 | 0.005 | 0.015 | 0.53 | |

| D | 0.03 | 0.025 | ||||||||||||||||

| E | 0.025 | 0.02 | ||||||||||||||||

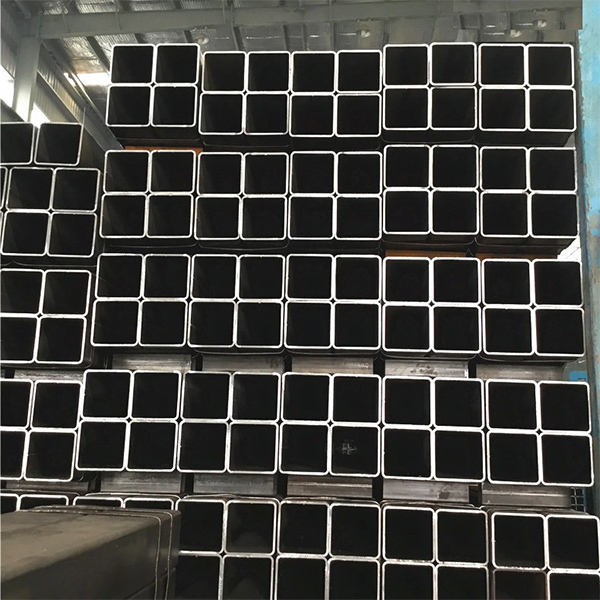

Bandhiga Alaabta