Dhuumaha dhuumaha L360 birta caadadii processing dhuumaha gaadiidka qaada

L360 Pipeline Steel, Ujeedada: API SPEC 5L-2011 (Pipeline Specification), oo uu sameeyay oo daabacay Machadka Batroolka Mareykanka, ayaa adduunka oo dhan laga isticmaalaa.Dhuumaha: Si looga qaado saliidda, gaaska ama biyaha dhulka iyada oo la marinayo tuubooyinka oo la geeyo warshadaha saliidda iyo gaaska.Dhuumaha dhuumaha waxaa ku jira laba nooc oo aan kala go 'lahayn iyo kuwa alxanka leh.Habka isku xirka waa alxanka dhamaadka, isku xirka hoop, xiriirka godka iyo wixii la mid ah.Waxyaabaha ugu muhiimsan ee tuubada waa B, X42, X46, X56, X65, X70 iyo kuwa kale ee birta ah.Shirkaddayadu waxay gudubtay shahaadada API (API 5CT iyo API 5L) Ogosto 2009.

L360 Pipeline Steel, API SPEC 5L GB/T9711.1 GB/T9711.2 Shiinaha Heerka Qaranka Codsiga: Ogsajiinta, tuubooyinka biyaha iyo saliidda ee warshadaha saliidda iyo gaaska dabiiciga ah B, X42, X52, X60, X65, X70 L245 L290 L320 L360 L390 L450 L485

Iyada oo horumarinta technology saxan birta dhuumaha iyo horumarka tuubooyinka welded samaynta, technology alxanka, kala duwan ee codsiga ee tuubada la tuubooyinka alxanka in si tartiib tartiib ah ballaarinta, gaar ahaan dhexroor weyn oo welded heerka fasalka faa'iidooyinka muuqda, iyo arrimo kharashka, Dhuumaha welded ayaa ku badnaa beerta xariiqda xariiqda, taas oo xaddidaysa horumarinta tuubooyinka birta ee birta aan fiicnayn.Sannadkii 2004, wax soo saarka dhuumaha aan xuduudda lahayn waxay ku saabsan yihiin 400,000 t, heerka birta waxaa ku jira X42-70, iyo noocyo kala duwan ayaa ah dhuumaha xeebta iyo dhuumaha badda hoostooda.

Wax soo saarka tuubooyinka birta heerka sare ah waxay qabataa habka daaweynta kulaylka microalloying, kharashka wax soo saarka ee birta birta ah ee birta ah ee birta ah ee birta ah ee birta ah ee birta ah ayaa iska cad in ay ka sarreyso tuubada welded, iyo hagaajinta darajada birta, sida X80 iyo wixii ka sareeya xadka tuubooyinka birta ee u dhigma , Habka caadiga ah ee tuubada aan qummanayn way adag tahay in la buuxiyo shuruudaha isticmaalayaasha;Mid kasta oo soo saaraha tuubooyin 12Cr1moV ah ayaa fulinaya shaqo cilmi baaris ah si loo wanaajiyo iska caabbinta daxalka ee tuubooyinka dhuumaha iyo waxqabadka xasilloon ee jawiga heerkulka hooseeya iyo sare.

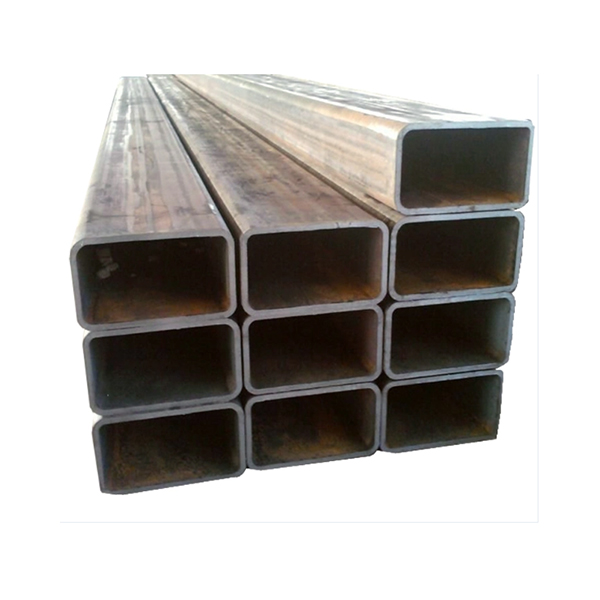

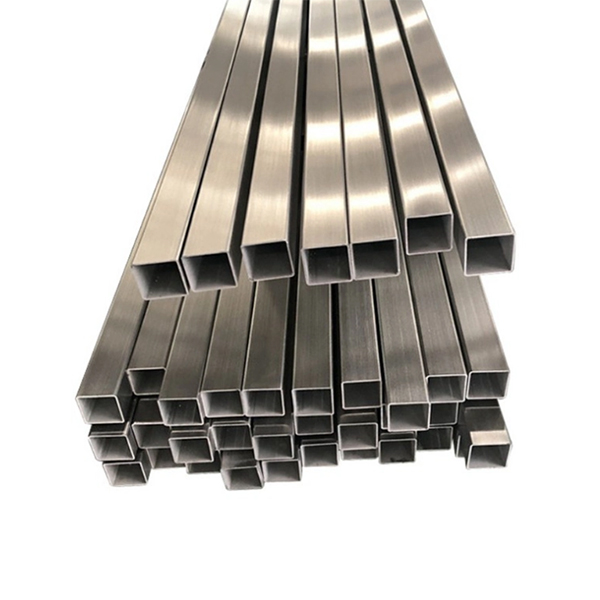

L360 Dhuumaha Birta, Qalabka

L245, L360, A53, J55, N80, X42, X46, X52, X56, X60, X65, X70

L360 Dhuumaha Birta, Tilmaamaha

60-630×1.53-40

Birta Dhuumaha L360, Guryaha Makaanikada

| heerka | sumadda | Xoog xajin (MPa) | Xoogga wax-soo-saarka (MPa) | tusay | elongation (%) | 0 ℃ saamaynta tamarta Akv (J)

| Xaaladda daaweynta kulaylka |

| API SPEC 5L GB/T9711.2 | B | ≥415 | 245-440 | ≤0.80 | 22 | ≥40 | Ma dabka |

| X42 | ≥415 | 290-440 | ≤0.80 | 21 | ≥40 | Ma dabka | |

| X52 | ≥460 | 360-510 | ≤0.85 | 20 | ≥40 | Ma dabka | |

| X60 | ≥520 | 415-565 | ≤0.85 | 18 | ≥40 | Ma dabka | |

| X65 | ≥535 | 450-570 | ≤0.90 | 18 | ≥40 | Dejin + xanaaq | |

| X70 | ≥570 | 485-605 | ≤0.90 | 18 | ≥40 | Dejin + xanaaq |

L360 Dhuumaha Birta, Kiimikada Ka kooban

| heerka | sumadda | Halabuurka kiimikada (%) | CEV (%) | |||||||

| C | Si | Mn | P | S | V | Nb | Ti | |||

| API SPEC 5L GB/T9711.2 | B | ≤0.16 | ≤0.40 | ≤1.10 | ≤0.020 | ≤0.010 | - | - | - | ≤0.42 |

| X42 | ≤0.17 | ≤0.40 | ≤1.20 | ≤0.020 | ≤0.010 | ≤0.05 | ≤0.05 | ≤0.04 | ≤0.42 | |

| X52 | ≤0.20 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.10 | ≤0.05 | ≤0.04 | ≤0.45 | |

| X60 | ≤0.21 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.15 | ≤0.05 | ≤0.04 | 协议 | |

| X65 | ≤0.16 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.06 | ≤0.05 | ≤0.06 | ≤0.45 | |

| X70 | ≤0.16 | ≤0.45 | ≤1.70 | ≤0.020 | ≤0.010 | ≤0.06 | ≤0.05 | ≤0.06 | ≤0.45 |

Fiiro gaar ah:1.0.015% ≤Altot<0.06%;N 0.012% ama ka yar;Al/N 2/1 ama ka sareeya;Cu 0.25% ama ka yar.Waa 0.30% ama ka yar.Cr 0.30% ama ka yar;Mo≤0.10% 2.V +Nb+Ti≤0.15 3.X60, X65, X70 Sida lagu heshiiyey Mo≤0.35% API SPEC 5L

Bandhiga Alaabta