Titanium alloy TA1 tube waa la isticmaali karaa i

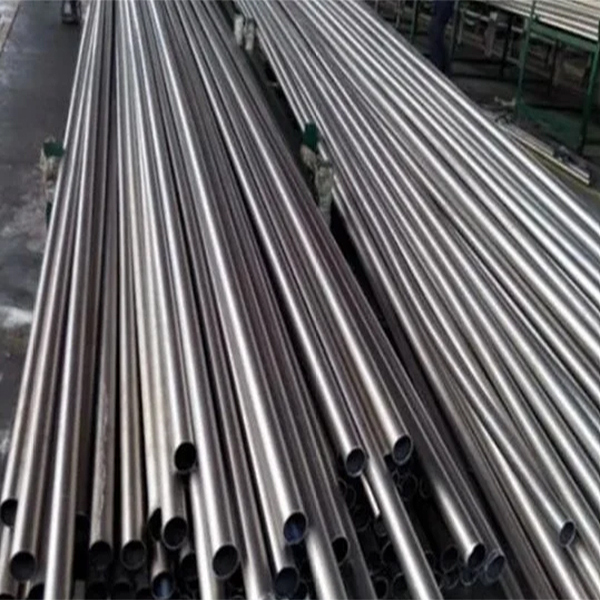

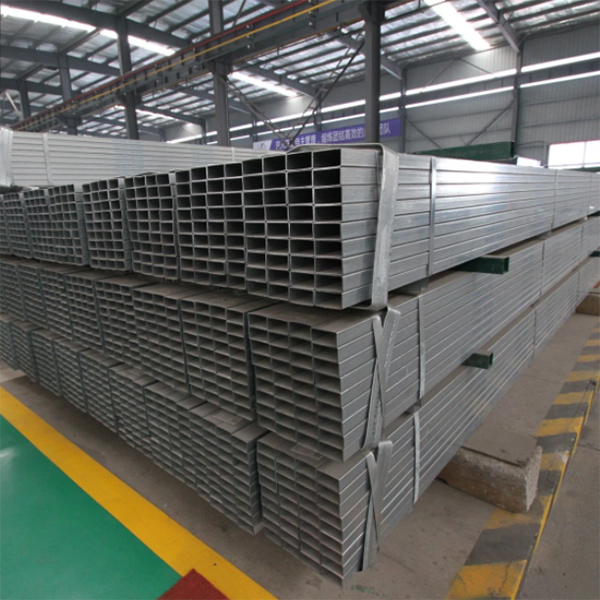

Titanium Alloy TA1 Tube, Waxay ka samaysan tahay daawaha titanium, kaas oo loo qaybin karaa saddex nooc sida uu qaab-dhismeedka.(1 Aluminium iyo tiin ayaa lagu daraa titanium. Aluminium, chromium, molybdenum, vanadium iyo walxo kale oo alwaax ah ayaa lagu daraa titanium. welded in noocyo kala duwan, alxanka xoogga wadajirka ah wuxuu gaari karaa 90% xoogga biraha matrix ah, iyo machinability wanaagsan.Tuubada Titanium waxay iska caabin sare u leedahay daxalka chloride, sulfide iyo ammonia.Iska caabbinta daxalka ee titanium-ka ee biyaha badda ayaa ka sarreeya tan aluminium aluminium, birta aan daxalka lahayn iyo daawaha saldhigga nikkel.Titanium sidoo kale waxay leedahay iska caabin biyo oo xoog leh.

Titanium Alloy TA1 Tube, Heerka ku habboon

GB/T 3620.1-2016 Titanium iyo darajooyinka daawaha aluminiumka iyo ka kooban kiimikaad

GB/T 3624-2010 Titanium iyo titanium alloy tube standard

Titanium iyo tuubooyinka daawaha ee titanium ee kulaylka beddelayaasha iyo kondensers

TA1, TA2 iyo TA3 waa titanium saafi ah warshadaha, kuwaas oo leh sifooyin farsamo sare, sifooyin shaabad aad u fiican, oo lagu alxan karaa noocyo kala duwan.Xoogga wadajirka ah ee welded wuxuu gaari karaa 90% xoogga birta matrixka, iyo waxqabadka goynta ayaa wanaagsan.Tuubada Titanium waxay iska caabin sare u leedahay daxalka chloride, sulfide iyo ammonia.Iska caabbinta daxalka ee titanium-ka ee biyaha badda ayaa ka sarreeya tan aluminium aluminium, birta aan daxalka lahayn iyo daawaha saldhigga nikkel.Titanium sidoo kale waxay leedahay iska caabin biyo oo xoog leh.

Loo isticmaalo samaynta tuubooyinka kondenser-ka ee biyaha badda wasakhaysan, biyaha leh xayndaab adag oo laalaaday, iyo heerka socodka sare.

Titanium Alloy TA1 Tube, Kala soocida

Sida laga soo xigtay histological

1. aluminium iyo walxaha daasadaha ayaa lagu daraa titanium.

2. Walxaha daawaha sida aluminium, chromium, molybdenum iyo vanadium ayaa lagu daraa titanium.

3. aluminium iyo vanadium ayaa lagu daraa titanium.

Daawaha Titanium wuxuu leeyahay awood sare iyo cufnaanta hoose, sifooyinka farsamada wanaagsan, adkaanta wanaagsan iyo iska caabinta daxalka.Intaa waxaa dheer: waxqabadka geeddi-socodka alloy titanium waa mid liidata, goynta adag.Habka kululaynta, aad bay u fududahay in la nuugo wasakhyada sida hydrogen, oxygen, nitrogen iyo carbon.Waxaa jira caabbinta xirashada liidata, habka wax soo saarka adag.

Waxaa loo qaybiyaa walxo isku dhafan

Alloy ku salaysan titanium oo leh walxo kale oo lagu daray.Wax-soo-saarka titanium-ka ee warshaduhu wuxuu bilaabmay 1948. Baahida horumarinta warshadaha duulista ayaa ka dhigaysa warshadaha titanium inay horumariyaan celcelis ahaan heerka kobaca sanadlaha ah ee ku saabsan 8%.Wax soo saarka sanadlaha ah ee agabka farsamaynta daawaha titanium ayaa gaadhay in ka badan 40,000 oo tan, ku dhawaad 30 nooc oo ah daawaha titanium.Alloys titanium inta badan la isticmaalo waa Ti-6Al-4V(TC4), Ti-5Al-2.5Sn (TA7) iyo titanium saafi ah warshadaha (TA1, TA2 iyo TA3).

Sida laga soo xigtay xarunta adeegga

Daawaha Titanium waxa loo qaybin karaa daawaha kulaylka u adkaysta, daawaha xoogga sare, daxalka u adkaysta daawaha (ti-molybdenum, ti-Palladium alloy, iwm), daawaha heerkulka hoose iyo daawaha shaqada gaarka ah (ti-iron kaydinta hydrogen iyo ti-nickel xasuusta). daawaha), iwm. Halabuurka iyo sifooyinka alaabooyinka caadiga ah ayaa lagu muujiyay shaxda.

Titanium Alloy TA1 Tube, Isticmaal

Titanium Alloy TA1 TubeBartamihii 1960-meeyadii, titanium iyo alloyskeeda ayaa guud ahaan warshadaha loo isticmaali jiray in laga sameeyo electrodes wershadaha korantada, kondhiriyeyaasha xarumaha korontada, kuleyliyaha sifaynta saliidda iyo nadiifinta biyaha badda, iyo qalabka xakamaynta wasakhda.Titanium iyo alwaaxyadeedu waxay noqdeen nooc ka mid ah qalabka dhismaha u adkaysta daxalka.Intaa waxaa dheer, waxaa sidoo kale loo isticmaalaa in lagu soo saaro qalabka kaydinta hydrogen iyo qaabeynta alloys xusuusta.

Shiinuhu wuxuu bilaabay inuu barto titanium iyo titanium alloys 1956. Bartamihii 1960-meeyadii, maadada titanium waa la warshadeeyay waxaana loo sameeyay TB2 alloy.

Halabuurka Kiimikada

| Darajo | N | C | H | Fe | THE | Al | IN | Waa hagaag | Mo | In | Of | Xoogga Jilitaanka (MPa) | Xoogga Wax-soo-saarka (MPa) | Dheeraynta(%) |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal | 240 | 138 | afar iyo labaatan |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal | 345 | 275 | 20 |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal | 450 | 380 | 18 |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | 550 | 483 | 15 | |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal | 895 | 828 | 10 |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal | 345 | 275 | 20 |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal | 620 | 70 | 15 |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 02-0.4 | 0.6-0.9 | Bal | 438 | 345 | 18 |

| Nooca | Waxaan sidoo kale bixin karnaa TB3, TB6, TC4, TC6, TC11, TC17, TC18 sida waafaqsan shuruudahaaga. | |||||||||||||

| Heerka | ASTM B348, ASTM F67, ASTM F136, ISO5832-2, ISO5832-3, AMS 4928, AMS 4930, ASTM F1295, ASTM F1713, MIL-T-9047 | |||||||||||||

| Codsiga | Metallurgy, Electronics, Medical, Chemical, Petroleum, Pharmaceutical, Aerospace, iwm. | |||||||||||||

Bandhiga Alaabta