TA2 titanium alloy tube ee isticmaalka warshadaha

TA2 Titanium Alloy Pipe, Faa'iidooyinka

TA2 Titanium Alloy Pipe, Marka la barbar dhigo qalabka kale ee birta ah, waxay leedahay faa'iidooyinka soo socda:

1. Xoog gaar ah oo gaar ah (xoogga cufnaanta / cufnaanta) (eeg jaantuska), xoogga culeysku wuxuu gaari karaa 100 ~ 140kgf / mm2, halka cufnaanta ay tahay 60% oo keliya birta.

2. Heerkulka heerkulka dhexdhexaadka ah waa wanaagsan yahay, heerkulka isticmaalka waa dhowr boqol oo darajo ka sarreeya aluminium aluminium, heerkulka dhexdhexaadka ah ayaa weli sii wadi kara xoogga loo baahan yahay, wuxuu ka shaqeyn karaa heerkulka 450 ~ 500 ℃ muddo dheer.

3. Iska caabin daxalka wanaagsan, dusha titanium ee jawiga isla markiiba sameeyay lakabka dharka iyo filimka oxide cufan, waxay awood u leedahay inay iska caabiso nabaad-guurka warbaahinta ee kala duwan.Titanium guud ahaan waxay leedahay iska caabin wanaagsan oo daxalka ah xagga oxidizing iyo warbaahinta dhexdhexaadka ah, gaar ahaan biyaha badda, koloriin qoyan iyo xalalka koloriinta.Laakiin dhimista dhexdhexaadka ah, sida xalalka hydrochloric acid, caabbinta daxalka titanium waa liidata.

4. Alloys Titanium oo leh waxqabad heerkul hooseeya iyo walxaha nadiifinta aadka u hooseeya, sida TA7, waxay ilaalin karaan balaastikada qaarkood -253 ℃.

5. Module jilicsan oo hooseeya, heerkulka kulaylka yar, ma laha feromagnetism.

6. adkaanta sare.

7. Hanti shaabad xumo iyo heerkulbeeg wanaagsan.

Daawaynta kulaylka Alloys Titanium waxay heli kartaa halabuurka waji kala duwan iyo qaab-dhismeed yar iyadoo la hagaajinayo habka daaweynta kulaylka.Waxaa guud ahaan loo arkaa in qaab-dhismeed yar oo siman oo siman uu leeyahay caag wanaagsan, xasilloonida kulaylka iyo xoogga daalka.Qaab dhismeedka acicular wuxuu leeyahay xoog waara oo sarreeya, xoog gurguurta iyo adkaanta jabka.Qaab-dhismeedyo isku-dhafan oo isku-dhafan oo siman ayaa leh sifooyin dhammaystiran oo wanaagsan.

TA2 Titanium Alloy Pipe, Hababka daawaynta kulaylka ee sida caadiga ah loo isticmaalo waa nuugista, xalinta iyo daawaynta gabowga.Annealing waa in la baabi'iyo walbahaarka gudaha, hagaajinta balaastikada iyo xasilloonida qaab-dhismeed yar, si loo helo sifooyin dhammaystiran oo wanaagsan.Guud ahaan, heerkulka annealing ee α alloy iyo (α+β) alloy waa 120 ~ 200 ℃ ka hooseeya barta kala guurka ee (α+β) -- →β wajiga.Xalka iyo daawaynta gabowga waa in la helo wejiga α 'iyo metastable β wajiga martensite by qaboojinta degdega ah ee gobolka heerkulka sare, ka dibna qurmay kuwaas oo wejiyada metastable iyadoo lagu hayo gobolka heerkulka dhexe, oo ay helaan qaybaha wajiga labaad ee ganaax kala firdhiyey. , sida wejiga α ama dhismaha, si loo gaaro ujeedada xoojinta daawaha.Caadi ahaan (alpha + beta) daawaynta daawaynta ee alfa + beta) -- -> barta kala-guurka wejiga beta ee ka hooseeya 40 ~ 100 ℃, beta alloy quenching in alpha + beta) -- -> dhibic marxaladda beta ee ka sarraysa 40 ~ 80 ℃.Heerkulka gabowga guud ahaan waa 450 ~ 550 ℃.Intaa waxaa dheer, si ay u buuxiyaan shuruudaha gaarka ah ee workpiece ah, warshaduhu waxay sidoo kale isticmaalaan labajibbaaran labajibbaaran, isothermal annealing, daaweynta kulaylka β, daaweynta kulaylka qallafsanaanta iyo habka daaweynta kulaylka kale ee birta.

TA2 Titanium Alloy Pipe, Kala soocida

Dhuumaha Titanium, tuubada alxanka titanium, titanium splicing tee, titanium splicing xusul, titanium alxanka giraanta, titanium yaraynta, Tii titanium, xusul titanium, shooladda titanium, iwm.

TA2 Titanium Alloy Pipe, Mabaadi'da Shaqada ee

TA2 Titanium Alloy Pipe, Inta badan isku xidhka dhammaan noocyada kala duwan ee dhuumaha qalabka titanium, loo isticmaalo wareegga walxaha u dhexeeya dhammaan noocyada kala duwan ee qalabka, dhuumaha ayaa iska caabin ah daxalka ee walxaha titanium laftiisa, si ay u beddelaan dhuumaha guud ee dhuumaha caadiga ah ma buuxin karaan baahida. .Guud ahaan ф 108 ee sare waa tuubooyinka alxanka.

Halbeegyada Farsamo ee ugu muhiimsan

| DN (mm) | Cabbiraadda dhexroorka dibadda (mm) | Qalabka |

| 15 | 18 | TA2 |

| 20 | 25 | TA2 |

| 25 | 32 | TA2 |

| 32 | 38 | TA2 |

| 40 | 45 | TA2 |

| 50 | 57 | TA2 |

| 65 | 76 | TA2 |

| 80 | 89 | TA2 |

| 100 | 108 | TA2 |

| 125 | 133 | TA2 |

| 150 | 159 | TA2 |

| 200 | 219 | TA2 |

| 250 | 273 | TA2 |

| 300 | 325 | TA2 |

| 350 | 377 | TA2 |

| 400 | 426 | TA2 |

| 450 | 480 | TA2 |

| 500 | 530 | TA2 |

| 600 | 630 | TA2 |

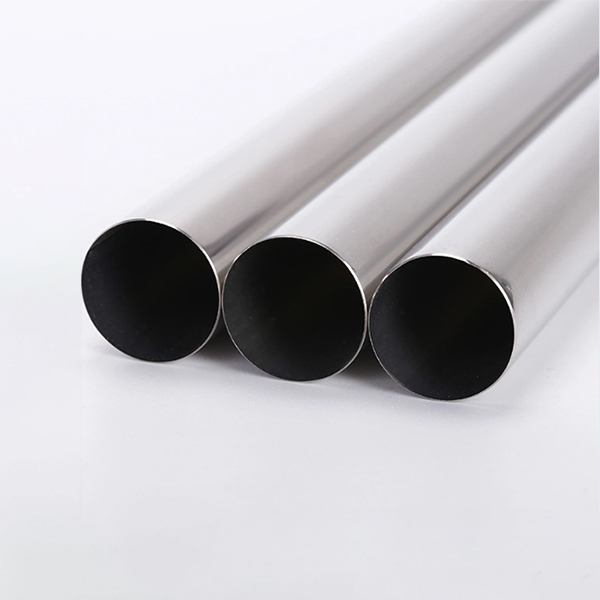

Bandhiga Alaabta