Tuubooyinka Bir-dhisme ee labajibbaaran

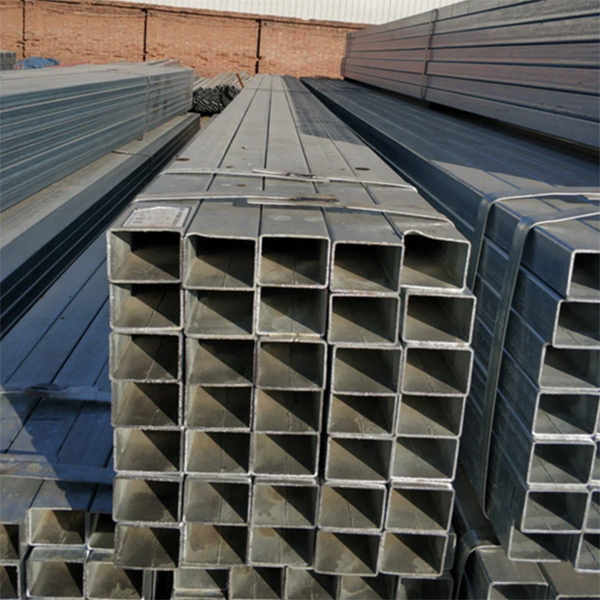

Tuubooyinka qaab dhismeedka labajibbaaran, oo sidoo kale loo yaqaano tuubada welded, waxay ka samaysan tahay saxan bir ah ama xariijimo ka dib markii ay samaysato tuubo labajibbaaran oo alxan leh.

Tuubooyinka qaab dhismeedka laba jibaaran, Qalabka sida caadiga ah loo isticmaalo waa: Q235A, Q235C, Q235B, 16Mn, 20#, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 018Cr19, Nini so

Dhuumaha birta welded ee qurxinta (GB/T 18705-2002), tuubada birta welded ee qurxinta dhismaha (JG/T 3030-1995), tuubada birta alxanka leh ee gaadiidka dareeraha cadaadiska hooseeya (GB/T 3091-2001), iyo Dhuumaha birta welded ee kulaylka beddelka (YB4103-2000).

Habka Waxsoosaarka

Tuubooyinka birta qaab dhismeedka labajibbaaran, meelaha cidhiidhiga ah waxaa loo isticmaali karaa in lagu soo saaro tubooyinka alxanka leh ee dhexroorka weyn leh, bannaanka ballaca isku midka ah ayaa loo isticmaali karaa in lagu soo saaro tuubooyinka alxanka leh ee dhexroorka kala duwan leh.Laakiin marka la barbar dhigo isla dhererka isku midka ah ee biibiile tol ah oo toosan, dhererka alxanka wuxuu kordhiyaa 30 ~ 100%, xawaaraha wax soo saarkuna wuu hooseeyaa.

Dhexroor weyn ama dhumucdiisuna waxay tahay tuubo dhismeed laba jibaaran, Guud ahaan waxaa si toos ah looga sameeyay billet billet ah, iyo tuubo yar oo welded tuubo alxan leh oo kaliya waxay u baahan tahay in si toos ah loogu alxanayo suunka birta.Ka dib dhalaalid fudud, siliggu waa diyaar.Sidaa darteed, dhexroorka yar ee tuubooyinka alxanka ah inta badan waxay isticmaalaan alxanka tollayn toosan, dhexroor weyn oo tuubooyinka alxanka ah inta badan waxay isticmaalaan alxanka wareegsan.

Qaabee Waxqabadka

tubbada birta qaab dhismeedka square, Waa magac loogu talagalay tuubooyinka labajibbaaran, kaas oo ah tuubada dhererka isku mid ah ee labada dhinac.Waxay ka samaysan tahay bir xariijimo ah iyada oo loo marayo habka xalinta iyo duubista.Caadi ahaan, xariijintu waa mid aan baakadaysan, fidsan, barafaysan, lagu alxanayo tuubo wareeg ah, ka dibna lagu rogo tuubada wareega ee Q215 oo alxanka tuubada labajibbaaran ka dibna la gooyaa dhererka baahida.Tirada caadiga ah waa 50 baakidhkiiba.Xoog waxaa loola jeedaa shaqada iska caabinta dhaawaca (qallafsanaanta balaastiigga saxda ah ama jabka) ee Q215 xogta tuubooyinka labajibbaaran ee alxanka hoostiisa culeyska taagan.Sababtoo ah culeyska qaabka jilicsanaanta, foosha, dabaysha, xiirid iyo siyaabo kale, sababtoo ah xoogga ayaa sidoo kale loo qaybiyaa xoogga xajinta, xoogga cadaadiska, xoogga foorarsiga, xoogga dhogorta iyo wixii la mid ah.Dhammaan noocyada xoogga badanaa waxay leeyihiin xiriir qeexan, isticmaalka caadiga ah ee xoogga xajinta sida irbadda xoogga aasaasiga ah.Awoodda iska caabinta burburinta waxaa loo yaqaannaa adkeysi kharash.

Culayska ku jira qaybaha horumarka weyn leh waxa loo yaqaan culays array.Awoodda, balaastikada iyo xagasha laga wada hadlay gadaasha xayndaabka qiimaha labajibbaaran ee tuubada adag ee hoos timaada ficilka culeyska culeyska birta ayaa ah dhammaan cabbiraadaha shaqada mashiinka hoos yimaada ficilka culeyska taagan ee Q215 welded tube square.Ficil ahaan, mashiinno badan ayaa ku jira shaqo soo noqnoqonaysa, deegaankan oo dhan fursadda daalka.Xagasha daalku waa in la miisaamo xogta birta jilicsan oo adag heerka irbadda.Habka ugu yar ee xagasha gudaha lagu hagaajiyo nolosha hadda jirta waa habka xagasha cadaadiska, taas oo ah in la isticmaalo tiro go'an oo ah nooca qaabka madaxa cadaadiska uu ku hoos jiro culeys gaar ah ayaa lagu riixaa la tijaabiyay Q215 welded data tube square, sida laga soo xigtay. cadaadiska heerka si loo go'aamiyo qiimaha xagasha.Hababka yar ee la isticmaalo waa HB, HRA, HRB, HRC iyo HV.Balaastii xaglaha waxaa loola jeedaa awoodda xogta birta ee culeyska saaran, qallafsanaanta caagga ah (qallafsanaanta joogtada ah) iyada oo aan waxyeello lahayn.Tuubo labajibbaaran oo caag ah oo alxan leh oo Q215 ah waa tuubbo labajibbaaran oo aan caadi ahayn oo aan caadi ahayn waa qaabaynta tuubo wareeg ah oo aan fiicneyn.Tuubbada aan kala go 'lahayn iyo dhibcaha alxanka macnaheedu waa, waa nooca tube madaxa labajibbaaran (tuubo torque), ruuxa noocyada badan ee agabka ayaa awood u leh inay ka dhigaan tuubo xisbi (tuubo torque square), waa dhexdhexaad ka, sababta, maxaa loo isticmaalaa. waa dhexe, laga tirada badan yahay Q215 welded tube bir laba jibaaran sida laga tirada badan yahay, ee qaab-dhismeedka tube square, tube cadcad, tuubada naqshadeeyayaasha (tuubo torque), iwm tube square Hordhac hawlaha tube square.

Halabuurka Kiimikada

S460N walxaha

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| ugu badnaan 0.2 | ugu badnaan 0.6 | 1 - 1.7 | ugu badnaan 0.8 | ugu badnaan 0.03 | ugu badnaan 0.025 | ugu badnaan 0.3 | ugu badnaan 0.1 | ugu badnaan 0.2 | ugu badnaan 0.025 | ugu badnaan 0.05 | ugu badnaan 0.05 | ugu badnaan 0.02 | ugu badnaan 0.55 | ugu badnaan 0.55 |

S420N walxaha

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| ugu badnaan 0.2 | ugu badnaan 0.6 | 1 - 1.7 | ugu badnaan 0.8 | ugu badnaan 0.03 | ugu badnaan 0.025 | ugu badnaan 0.3 | ugu badnaan 0.1 | ugu badnaan 0.2 | ugu badnaan 0.025 | ugu badnaan 0.05 | ugu badnaan 0.05 | ugu badnaan 0.02 | ugu badnaan 0.55 | ugu badnaan 0.52 |

Waxyaabaha S420NL:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| ugu badnaan 0.2 | ugu badnaan 0.6 | 1 - 1.7 | ugu badnaan 0.8 | ugu badnaan 0.025 | ugu badnaan 0.02 | ugu badnaan 0.3 | ugu badnaan 0.1 | ugu badnaan 0.2 | ugu badnaan 0.025 | ugu badnaan 0.05 | ugu badnaan 0.05 | ugu badnaan 0.02 | ugu badnaan 0.55 | ugu badnaan 0.52 |

Waxyaabaha S460NL:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| ugu badnaan 0.2 | ugu badnaan 0.6 | 1 - 1.7 | ugu badnaan 0.8 | ugu badnaan 0.025 | ugu badnaan 0.02 | ugu badnaan 0.3 | ugu badnaan 0.1 | ugu badnaan 0.2 | ugu badnaan 0.025 | ugu badnaan 0.05 | ugu badnaan 0.05 | ugu badnaan 0.02 | ugu badnaan 0.55 | ugu badnaan 0.55 |

Guryaha Makaanikada

S460N walxaha

| Dhumucda magaca ah (mm): | ilaa 100 | 100 - 200 |

| Rm- Xoog xajin (MPa) | 540-720 | 530-710 |

| Dhumucda magaca ah (mm): | ilaa 16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 100 | 100 - 150 | 150 - 200 |

| ReH-Awood dhalidda ugu yar (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Saamaynta tamarta (J) longitud., (+N) | +20° 55 | 0° 47 | -10° 43 | -20° 40 | |

| KV- Saamaynta tamarta (J) beddelka, (+N) | +20° 31 | 0° 27 | -10° 24 | -20° 20 | |

| Dhumucda magaca ah (mm): | ilaa 16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 200 |

| AMin.elongation Lo = 5,65 √ Markaa (%) | 17 | 17 | 17 | 17 | 17 |

S420N walxaha:

| Dhumucda magaca ah (mm): | ilaa 100 | 100 - 200 | 200 - 250 |

| Rm- Xoog xajin (MPa) | 520-680 | 500-650 | 500-650 |

| Dhumucda magaca ah (mm): | ilaa 16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 100 | 100 - 150 | 150 - 200 | 200 - 250 |

| ReH-Awood dhalidda ugu yar (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Saamaynta tamarta (J) longitud., (+N) | +20° 55 | 0° 47 | -10° 43 | -20° 40 | |

| KV- Saamaynta tamarta (J) beddelka, (+N) | +20° 31 | 0° 27 | -10° 24 | -20° 20 | |

| Dhumucda magaca ah (mm): | ilaa 16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 200 | 200 - 250 |

| AMin.elongation Lo = 5,65 √ Markaa (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Waxyaabaha S420NL:

| Dhumucda magaca ah (mm): | ilaa 100 | 100 - 200 | 200 - 250 |

| Rm- Xoog xajin (MPa) | 520-680 | 500-650 | 500-650 |

| Dhumucda magaca ah (mm): | ilaa 16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 100 | 100 - 150 | 150 - 200 | 200 - 250 |

| ReH-Awood dhalidda ugu yar (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Saamaynta tamarta (J) longitud., (+N) | +20° 63 | 0° 55 | -10° 51 | -20° 47 | -30° 40 | -40° 31 | -50° 27 | |

| KV- Saamaynta tamarta (J) beddelka, (+N) | +20° 40 | 0° 34 | -10° 30 | -20° 27 | -30° 23 | -40° 20 | -50° 16 | |

| Dhumucda magaca ah (mm): | ilaa 16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 200 | 200 - 250 |

| AMin.elongation Lo = 5,65 √ Markaa (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Waxyaabaha S460NL:

| Dhumucda magaca ah (mm): | ilaa 100 | 100 - 200 |

| Rm- Xoog xajin (MPa) | 540-720 | 530-710 |

| Dhumucda magaca ah (mm): | ilaa 16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 100 | 100 - 150 | 150 - 200 |

| ReH-Awood dhalidda ugu yar (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Saamaynta tamarta (J) longitud., (+N) | +20° 63 | 0° 55 | -10° 51 | -20° 47 | -30° 40 | -40° 31 | -50° 27 | |

| KV- Saamaynta tamarta (J) beddelka, (+N) | +20° 40 | 0° 34 | -10° 30 | -20° 27 | -30° 23 | -40° 20 | -50° 16 | |

| Dhumucda magaca ah (mm): | ilaa 16 | 16 - 40 | 40 - 63 | 63 - 80 | 80 - 200 |

| AMin.elongation Lo = 5,65 √ Markaa (%) | 17 | 17 | 17 | 17 | 17 |

Bandhiga Alaabta