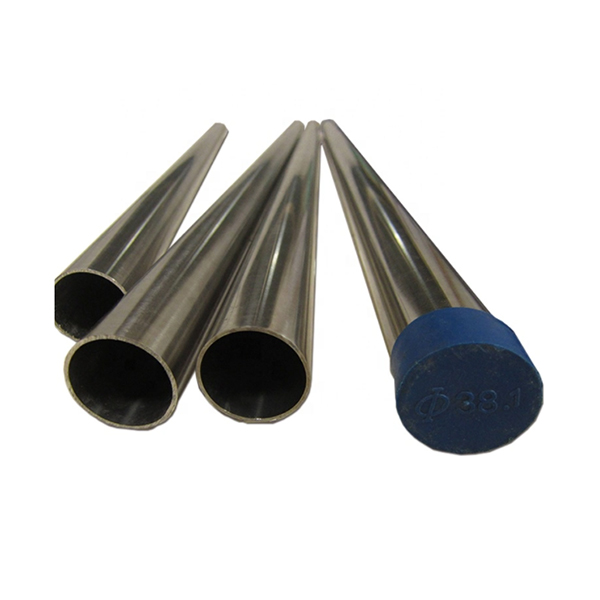

Tube-ka birta ah ee birta ah ee aan xidhnayn

Tuubbada birta ah ee kulul ee duuban, duubista kulul waxay la mid tahay rogid qabow, duubitaan qabow ayaa ka hoos wareegaya heerkulka dib-u-crystalization, iyo duubitaan kulul ayaa ka sarraysa heerkulka dib-u-curystallization.

Tube-Bir aan Xirnayn oo Kulul, Faa'iidooyin

Waxay burburin kartaa qaab-dhismeedka wax-soo-saarka birta birta ah, waxay nadiifin kartaa cabbirka hadhuudhka ee birta, waxayna baabi'in kartaa cilladaha yaryar, si qaab-dhismeedka birta la isku duubo oo loo hagaajiyo sifooyinka farsamada.Horumarkani waxa uu inta badan ka muuqdaa jihada rogrogasha, si aanay birtu u noqon mid isotropic ilaa xad.Xumbo, dildilaacyo iyo dabacsanaan la sameeyay inta lagu jiro shubista ayaa sidoo kale lagu alxan karaa heerkul sare iyo cadaadis.

Kala soocidda

Hot Rolled Seamless Steel Tube, Waxay u qaybsan tahay birta guud ee birta, tuubada birta kuleyliyaha cadaadiska hooseeya iyo dhexdhexaadka ah, tuubada birta kuleyliyaha cadaadiska sare, dhuunta birta ah ee birta ah, tuubada birta ah, tuubada dildilaaca batroolka, tuubooyinka birta juqraafiyeed iyo tuubooyinka kale ee birta.

Qabow duuban (dial) tuubo bir ah oo aan kala go 'lahayn marka lagu daro tuubbada birta guud, cadaadiska hoose iyo dhexe ee tuubada birta, tuubada birta kuleyliyaha cadaadiska sare, tuubada birta daawaha, tuubada birta ah, tuubada dildilaaca batroolka, tuubooyinka kale ee birta, sidoo kale waxaa ku jira kaarboon khafiif ah- Dhuumaha birta gidaarka leh, dhuunta birta ah ee dhuuban, dhuunta birta ah, tuubo bir ah oo qaab gaar ah u samaysan.Dhexroorka dibedda ee tuubada duuban ee kulul ee bilaa-jilicsan ayaa guud ahaan ka weyn 32mm dhumucdiisuna waa 2.5-75mm.Dhexroorka dibadda ee tuubada birta ah ee duuban ee qabow waxay gaari kartaa 6mm dhumucdiisuna waxay gaari kartaa 0.25mm.Dhexroorka dibadda ee tuubooyinka dhuuban wuxuu gaari karaa 5mm dhumucdiisuna waxay ka yar tahay 0.25mm.

Dhuumaha guud ee birta ah: waxay ka samaysan tahay 10, 20, 30, 35, 45 iyo birta kale ee tayada sare leh ee carbon bond 16Mn, 5MnV iyo birta qaab dhismeedka hoose ee hoose ama 40Cr, 30CrMnSi, 45Mn2, 40MnB qabow duuban.10, 20 iyo birta kale ee yar ee kaarboon wax soo saarka tuubooyinka aan xuduud lahayn ayaa inta badan loo isticmaalaa dhuumaha dareeraha.45, 40Cr iyo bir kale oo dhexdhexaad ah oo kaarboon ah oo laga sameeyay tuubo aan xuduud lahayn si loo soo saaro qaybo farsamo, sida baabuurta, cagafyada qaybo culayska saarayIsticmaalka guud ee birta birta ah ee aan sinnayn si loo hubiyo awoodda iyo tijaabada fidinta.Tuubooyinka birta duuban ee kulul waxaa lagu keenaa kuleyl duuban ama xaalad kulayl lagu daweeyay.Dhalmada qabowga duuban waa kulayl - la daweeyaa.

Weecashada la oggol yahay ee dhexroorka bannaanka caadiga ah

D1 ± 1.5%, ugu yaraan ± 0.75mm

D2 lagu daray ama laga jaray 1.0%.Ugu yaraan +/- 0.50 mm

D3 +/ - 0.75%.Ugu yaraan +/- 0.30 mm

D4 +/- 0.50%.Ugu yaraan +/- 0.10 mm

qaacidada xisaabinta miisaanka tuubada birta

[(dhexroorka dibadda - dhumucda gidaarka)* dhumucda gidaarka] x0.02466=kg/m (miisaanka halkii mitir)

Tuben Bir ah oo aan Xirnayn oo Kulul, Ujeeddooyin Hawleed

1. Qaybta dhismaha waa: hoos gaadiidka dhuumaha waa ka badan, saarista dhismaha ee biyaha dhulka hoostiisa, kuleyliyaha gaadiidka biyaha kulul.

2. Farsamaynta makaanikada, gacan-galka, qalabka farsamaynta, iwm.

3. Koronto: gudbinta gaaska, dhuumaha dareeraha tamarta biyaha.

4. Wershadda tamarta dabaysha tuubooyinka antistatic, iwm.

Tilmaamid

| Magaca alaabta | Dhuumaha birta ah ee birta ah |

| Heerka | ASME, ASTM, EN, BS, GB, DIN, JIS iwm |

| Summada | 201/202/304/304L/316/316L/ 321/309S/310S/410/420/430 |

| Shahaado | BV, ISO, CE, SGS iwm |

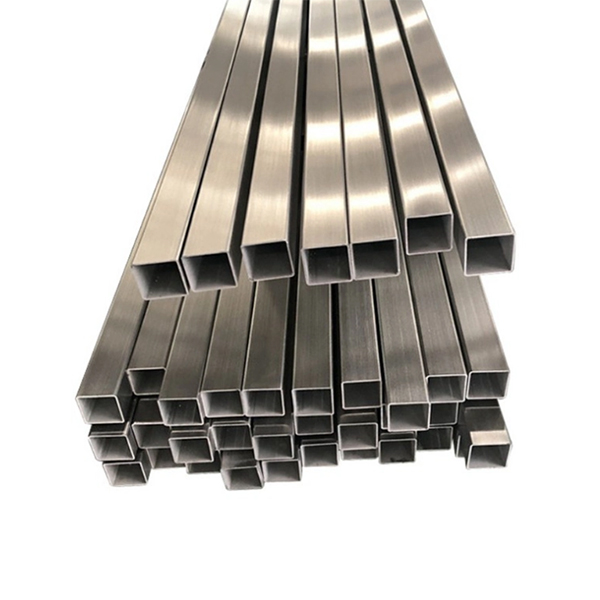

| Nooca | Aan lahayn & alxan |

| Dhexroorka Dibadda (OD) | 3-1220mm |

| Dhumucda | 0.5-50mm |

| Dhererka | 6000mm 5800mm 12000mm ama Customized |

| Farsamada | Qabow la sawiray ama la sawiray |

| Dusha sare | 2B, No.1, No.4, HL, BA, 8K iwm |

| Codsiga | Warshadaha, Kiimikada, Korontada, Mashiinada, Dhismaha, Qurxinta, iwm. |

| Baakad | Baakadaha dhoofinta caadiga ah ee badda u qalma |

| Waqtiga dirida | 7-15 Maalmo Shaqo Kadib Debaajiga |

| Shuruudaha Ganacsiga | FOB, CFR, CIF, EXW |

| Shuruudaha Lacag-bixinta | 30%T/T,L/C |

Daaweynta Dusha sare

| Dusha sare | Qeexid | Codsiga |

| No.1 | Dusha sare waxay ku dhammaatay daawaynta kulaylka iyo qajaarka ama hababka u dhigma halkaas ka dib rogid kulul. | Taangiga kiimikada, tuubooyinka iwm. |

| No.3 | Kuwa ku dhammeeyey in lagu nadiifiyo No.100 ilaa No.120 abrasives ee ku qeexan JIS R6001. | Qalabka jikada, dhismaha dhismaha iwm. |

| No.4 | Kuwa ku dhammeeyey in lagu nadiifiyo No.150 ilaa No.180 abrasives ee ku qeexan JIS R6001. | Maacuunta jikada, dhismaha dhismaha, qalabka caafimaadka iwm. |

| 2B | Kuwa la dhammeeyey, ka dib duubista qabowga, daawaynta kulaylka, qajaarka ama daawaynta kale ee u dhiganta iyo ugu dambaynta in qabow lagu duubo oo la siiyo dhalaal habboon. | Qalabka caafimaadka, warshadaha cuntada, qalabka dhismaha, weelka jikada iwm. |

| BA (No.6) | Kuwa lagu farsameeyay daawaynta kulaylka dhalaalaysa ka dib duubista qabowga. | Qalabka jikada, Qalabka Korontada, Dhismaha dhismaha iwm. |

| Muraayada (No.8) | U iftiimaya sida muraayadda | Dhismaha dhismaha, qurxinta iwm. |

| Timaha timaha | Kuwa dhammeeyey turxaan bixintu si ay u siiyaan xariijimo si joogto ah u dhalaalaysa iyaga oo isticmaalaya naaxinta cabbirka hadhuudhka ku habboon. | Dhismaha dhismaha iwm. |

Halabuurka Kiimikada

| Darajo | C | Si | Mn | P | S | Ni | Cr | Mo | |||||

| 201 | ≤0.15 | ≤0.75 | 5. 5-7.5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16.0 -18.0 | - | |||||

| 202 | ≤0.15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - | |||||

| 301 | ≤0.15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - | |||||

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - | |||||

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - | |||||

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - | |||||

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - | |||||

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | ||||||

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0- | |||||

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16.0 -1 8.0 | 2.0 - | |||||

| 321 | ≤ 0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - | |||||

| 630 | ≤ 0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - | |||||

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - | |||||

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0 · 28.0 | 19.0-23.0 | 4.0-5.0 | |||||

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 | |||||

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | |||||

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0.22 | 0. 24-0 .26 | - | |||||

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - | |||||

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - | |||||

| Alaabta Magaca | Qalab | Heerka | Cabbirka (mm) | Codsiga | |||||||||

| Tuubbada heerkulka hooseeya | 16MnDG 10MnDG 09DG 09Mn2VDG 06Ni3MoDG ASTM A333 | GB/T18984- 2003 ASTM A333 | OD: 25mm ~ 508mm WT: 3mm ~ 100mm | Codso -45 ºC ~ 195 ºC weelka cadaadiska heerkulka hoose iyo tuubada kulaylka hooseeya | |||||||||

| Tuubbada kululeeyaha cadaadis-sare | 20G ASTMA106B ASTMA210A ST45.8-III | GB5310-1995 ASTM SA106 ASTM SA210 DIN17175-79 | OD: 8-1240* WT:1-200 | Ku habboon soo saarista tuubada kululeeyaha cadaadiska sare, madaxa, tuubada uumiga, iwm | |||||||||

| Tuubada dildilaaca batroolka | 10 20 | GB9948-2006 | OD: 8-630* WT:1-60 | Loo isticmaalo tuubada foornada sifaynta saliidda, tuubada kulaylka beddelka | |||||||||

| Tuubbada kululeeyaha cadaadiska dhexdhexaadka ah oo hooseeya | 10 # 20# 16Mn,Q345 | GB3087-2008 | OD: 8-1240* WT:1-200 | Ku habboon soo saarista qaab-dhismeedka kala duwan ee kuleyliyaha cadaadiska hooseeya iyo dhexdhexaadka ah iyo kuleyliyaha lugaha | |||||||||

| Qaab dhismeedka guud ee tuubada | 10#,20#,45#,27SiMn ASTM A53A,B 16Mn,Q345 | GB/T8162- 2008 GB/T17396- 1998kii ASTM A53 | OD: 8-1240* WT:1-200 | Codso qaab dhismeedka guud, taageerada injineernimada, farsamaynta farsamada, iwm | |||||||||

| Daboolka saliidda | J55,K55,N80,L80 C90,C95,P110 | API SPEC 5CT ISO11960 | OD: 60-508* WT:4.24-16.13 | Waxaa loo isticmaalaa soo saarista saliidda ama gaaska ku jirta saliidda ceelasha, loo isticmaalo saliidda iyo ceelka gaaska dhinaceeda | |||||||||

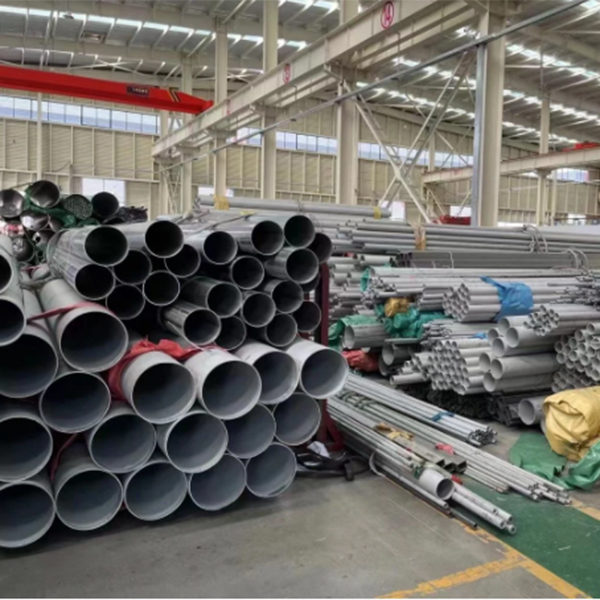

Bandhiga Alaabta